Life of Richard Trevithick by F. Trevithick: Volume 1: Chapter 16

CHAPTER XVI. RECOIL ENGINE AND TUBULAR BOILER.

BRIDGENORTH,

7th May, 1815

Mr. GIDDY,

Sir,— Yesterday I fixed the pumps to the new engine exceedingly well.

The bucket is 24.5 inches diameter, 18.5 feet high, stroke 3 feet, works fifteen strokes per minute, with about 28 lbs. of coal per hour. The arms are 15 feet from point to point, but only one of them gives steam. They run twenty rounds for one stroke of the engine, which is worked by a strap, like a common lathe. The steam was about 100 lbs. to the inch. The opening in the arm was about half an inch long, by a quarter of an inch wide. I intend to work the steam much higher. The fire-place is one tube in another. The fire-tube is 172 inches diameter, the outer tube 24 inches, 9 feet high. It stands perpendicular. I shall continue to make several experiments, and will give you the results, but as yet cannot say much about it, as it was late yesterday before I finished it.

I am convinced that it has by far the greatest power for the consumption of coal that was ever made. When I consider the friction in this small machine and the small fire-place, where there is not above three gallons of coal, with the work it performs, I can scarcely believe my own eyes. I have written by this post to Cornwall to desire the Foxes to send up their engineer to inspect it. The large engine is begun, according to the drawings.

It will be about thirty-five times the fire sides and fireplace of this small engine. I think it will do fifty times the work, because the friction will be much less in a large than in a small machine. The expense will be about £800, and the power will be equal to a 70-inch cylinder double power. I shall be able to carry every part of this powerful engine on my back (boiler excepted). I would be much obliged to you to inform me what speed you think would be the best for the ends of the arms to travel.

I remain, Sir,

Your very humble servant,

RICHARD TREVITHICK

This overcrowding of invention on invention was beneficial to the country, prompting others to complete and make useful the ideas so freely scattered, but it had the effect of retarding the perfection of any one in particular.

The screw-propeller, in itself complete, was tied to the incomplete recoil engine, which in its turn was hampered with the new multitubular boilers, of novel construction, and giving steam of greatly-increased pressure. The main object of the recoil engine was to avoid complexity of machinery, and consequent weight in marine steam propulsion.

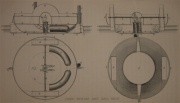

The recoil engine consisted of two arms, in form like the scabbard of a cavalry sword, each arm 7 feet 6 inches long, projecting from an axis. Steam passed through those hollow arms, and escaping through a small hole near the end, its impact on the surrounding air caused the arms to be forced into circular movement. The propelling screw in the steam-vessel was to be attached to the same axle. A belt-wheel fixed on the shaft drove a pump for the purpose of practically testing the economical power of the engine. The boiler, of novel construction, though its simplicity almost leads to its being called not at all new, was his comparatively old tubular boiler shifted from the horizontal position to the vertical. Yet the two boilers in operation were totally distinct things, the new one being suitable and convenient for the hold, taking up little room, and not liable to have portions injuriously exposed to the fire from the roll of the vessel. That portion of the fire-tube above the water-line was an effective substitute for what has since been patented as the superheating steam apparatus, and at the same time served as a portion of the chimney. The working steam-pressure was 100 lbs. to the inch. Several experiments were tried by altering the size of the escape-hole in the end of the revolving arm from a quarter of an inch long, by one thirty-second of an inch wide, through various widths up to half an inch wide. The speed of the arm was from 10,000 to 15,000 feet a minute. Richard Preen, who saw it work, gave the following recollections

I am now seventy years old, and was working in 1809 in John Hazeldine's engine foundry at Bridgenorth, and have been there most of my time. About that time Mr. Trevithick came very often to the foundry. The engines Hazeldine was building were called Trevithick's engines. The outer boiler was a cast-iron cylinder like a barrel, about 5 feet in diameter. The fire was inside in a wrought-iron tube. The cylinder was let into the boiler, the four-way cock had a handle that was knocked up and down. The piston-rod had a cross-bead, and two side rods went down, one to the pin in the fly-wheel, the other to a pin in the cog-wheel; some of them had a crank on one end of the shaft instead of the cog-wheel.

Mr. Trevithick made another kind of engine, called the Model, some people called it the Windmill, and said it was intended to throw balls against the French. There were two great arms, each of them 10 or 12 feet long, placed opposite one another on a hollow shaft or axle, which had a nozzle in it When steam was turned on it puffed out at the ends of the arms, and they went around like lightning, with a noise like shush ! shush ! so then it was called by that name.

This engine was made just before Mr. Trevithick went to South America. He did not know what to do with it, and so gave it a present to Jones, the foreman in the works.

Master and Jones had a pretty quarrel about who should have it afterwards.

Mr. Rastrick was considered the engineer. He quarrelled with Hazeldine about putting up the Chepstow Bridge, and set up for himself at West Bromwich, to construct portable engines, the same as they made for Mr. Trevithick.

He sent word to me to come to work for him. I was then working one of Mr. Trevithick's engines in Mr. Sing's tan-yard. They said they would put me in prison if I left them. That was about 1818.

Mr. Hazeldine's brother (William Hazeldine) lived at Shrewsbury. He built Bangor Bridge.

A Spaniard came once or twice with Mr. Trevithick. I was getting the core out of one of the cast-iron boilers before it was cold, for fear of straining the iron. The Spaniard sent for quarter of a cask of beer because we worked hard. Several engines and plunger-pumps were made, no piece to be larger than a mule could carry.[1]

HAZELDINE'S FOUNDRY,

BRIDGENORTH,

May 12th, 1815

DAVIES GIDDY, ESQ., M.P.

Sir, —I have received both your favours, which I cannot clearly understand. You say that the point of the arm ought to go five-sixths of the speed of the fluid, which under one atmosphere would be 1070 feet per second, and to increase as the pressure and speed of the fluid increases. Suppose one atmosphere, or 15 lbs. to the inch, to be 1,070 feet per second for the point of the arm to go, four atmospheres, or 60 lbs. to the inch, would be 2,070 feet per second for the point of the arm to go 16 atmospheres, or 240 lbs. to the inch, would be 4,140 feet per second; this would be a speed more than double a cannon-ball, and such as can never be obtained in practice and while working in fluid instead of vacuum.

The speed of the fluid does not increase after the pressure of one atmosphere.

I cannot make out why the speed of the arm should ever increase beyond 1070 feet per second; but as you have given it so much thought, I doubt not your calculations are right, and I only wish to understand you, whether the speed of the arm should never exceed 1,070 feet per second, under all pressures, or whether it is to increase as I have stated above. If so, it will go so far beyond practice that I must lose a Part of the power for a less speed, so as to accommodate it to general use. What do you suppose the loss was in working 225 feet per second, which was about the rate in the data that I gave you in my first letter?

Suppose I make the large engine for which I am now making the drawings to go with a speed of 350 feet per second, what part of the whole power should I get in that case, or what deficiency would there be to deduct from the 3/8ths which you call the best data? As I have not yet begun that part of the machine, I can alter it to any speed you think proper, and I will do so; but that is a speed that is suitable to the screw on the first motion, and a speed that the centres will stand well. I am-doubtful whether the speed is so great on steam as the theory of air gives, because I find that the arm that contains the steam holds about 30 feet long of 1 inch square of steam, and when the discharge-hole at the end of it has an opening of 0.5 inch by 3/16ths, which is about one tenth of a square inch, when the throttle-cock is suddenly shut, the steam continues to discharge for four seconds, first strong, and gradually falling down from 100 lbs. to the inch to atmosphere strong. I have not worked the engine to any advantage since I wrote to you last, because before working with very high steam I wished to force the boiler with cold water, which I did with 300 lbs. to the inch. It stood exceedingly well; only in a few critical places, in angles where the smiths could not come to close the rivets well the cement has been forced from between the plates, but no alteration in the shape, nor has any part given way. 999 parts of the boiler out of the 1,000 did not leak a single drop. I am now getting out the few leaking rivets, and shall then try it again. I find a great deal of difficulty in keeping the water in the boiler from getting away with the steam; the one tube being 18 inches diameter, and the other only 2 feet diameter, leaves but 3 inches space on each side, or but 2 superficial feet of surface of water to give out the steam, which comes with such violence that it brings the water with it, unless it is 5 feet below the boiler-top, obliging me to lose near one-half of my fire sides in the inner tithe.

About a foot and half down from the top I put a quantity of hemp, and loaded it with small pieces of iron like a teaching, to serve as a sift for the water, but though it mends it, yet it is not a cure. I have taken a patent, and shall put in my specification as soon as I return to London, which I expect will be in the course of ten or twelve days.

I remain, Sir,

Your very humble servant,

RICHARD TREVITHICK.

P.S.— I have drawn the cylinder 9 feet diameter, in which the screw is to work, which will be 8 feet 10 inches in diameter; having two turns in 4 feet long, of course it will gain 2 feet forward to each turn and to each round of the steam-arms, the same as the screw, being on the first motion. At a rate of about 350 feet per second on the end of the arm, will give the screw about ten miles forward per hour.

The recoil engine was not quite satisfactory, for the steam issued from the aperture for four seconds after the supply had been shut off, showing a loss of power during its passage through the arm: one hoped-for means of obviating it was to get stronger steam. The gossip that the new engine was to throw balls against the French, and Trevithick's calculation coupling speed of the arms with that of a cannon-ball, are as floating straws indicating that the current of conversation still ran on the possibility of attacking the French by steam, though the method was shifted from the steam fire-ship to the centrifugal steam-catapult.

BRIDGENORTH,

May 16th, 1815.

DAVIES GIDDY, ESQ., M.P.,

Sir,— The boilers making for this towing engine are all tubes, of 3 feet diameter, 5/8ths of an inch thick, with circular ends, of wrought iron.

There are three horizontal tubes, to each of which three other tubes are suspended, which will all be fixed or hung up in a large chimney, thus:—

Though I have called it stone-work, it will have for portable purposes an outside case of iron luted with fire-clay, but for fixtures, stone-work. I am satisfied that for rotary engines it will do well, but for engines lifting water the speed must be so reduced that it will be more expensive for that purpose than other machinery. I have been •thinking of a method to use high steam in another way for that purpose, of which I sent a sketch for your inspection. Suppose I work with 200 lbs. to the inch pressure, which, in theory, the tubes on the other side will stand, according to the experience in proving wrought-iron cables, which stand 50,000 lbs. to the square inch of iron, above 2,000 lbs. to the inch on the tubes; therefore the pressure I intend to work with will be only 10 per cent. of the real strength. Suppose a common plunger piece and pole to be placed over the shaft, or a little below the surface, to stand on a beam of wood across the pit, on each side the iron plunger-pole side rods connect to the shaft rods below.

From the bottom of the plunger-piece a small pipe conveys water forward and backward to a steam-vessel, which water would pass and repass every stroke by the steam pressing on the surface of the water in the steam-vessel.

This would not need an engine-house or beam. The whole could be fixed complete (boiler excepted), of the power of the Watt 63-inch double, for £250 or £300, because a 20-inch plunger-pole would give that power.

By this plan the expansive steam might be used. Would the steam on the surface of the water heat it above the boiling point, and then imbibe heat and again discharge it, as the pressure of the steam is thrown on and off, or would it not answer to Put a float of cork on the water?

By this plan the packing could be kept tight with any pressure.

The heavy rods would take the advantage of the expansion of strong steam, and I cannot see but that the engine would be manageable with 3-inch valves, which would be easily worked.

The whole expense of the machine would not exceed £1,000, for a power equal to a 63-inch double-power engine of Watt.

I remain, Sir,

Your very humble servant,

RICHARD TREVITHICK.

Within a week from the trial of the simple vertical wrought-iron boiler with fire in the tube, he had de- signed and was putting into execution an entirely new boiler, composed of numerous tubes, and giving steam of 200 lbs, to the inch. To avoid the loss of power by loss of heat which had been observed in the recoil arm, he thought of forcing water through it in lieu of steam; but to make it more intelligible to his friends, be applied the idea to one of his pole-engines. The following letters give indications of experiments with various forms of tubular boilers:-

TREDREA,

December 31st, 1815.

DEAR TREVITHICK,

I have really been uneasy on one point since I saw your engine at Herland, and that in respect to the raising of sufficient steam. There is without doubt sufficient surface, but then a great part of the long tubes will be remote from the fire, and consequently, I fear, of but little power for raising steam. I should very much have preferred using four or five shorter tubes arranged in this manner.

It is difficult to give any reason for the greater power of fire applied in this manner, but there seems to be no reason for doubting the fact.

No alteration can, however, now be made, and I shall wait with much anxiety for an account of the engine's performance.

You will not forget the Geological Society. I am not even desirous of beautiful or costly specimens. What I request is that you will furnish us with samples of the different countries producing the silver ore, and specimens of the lodes in their bulk and in depth. I shall leave Tredrea on some day of the second week in January; but it may be as well to direct to me here, as I shall leave directions with the Post Office at Marazion about forwarding my letters.

Yours, ever most faithfully,

DAVIES GIDDY

Mr. Davies Giddy's sketch is very like the fixing of tubes in modern locomotive fire-boxes his words do not fully explain his views. My friend and railway companion in work, the late Mr. Henry Booth, has been called the inventor of the tubular boiler, used in Stephenson's trial locomotive, the 'Rocket,' in 1829 while Trevithick and the President of the Royal Society freely corresponded on the principles of such boilers and their practical construction fifteen years before, when they were not only used with higher pressure steam than Booth dreamt of, but were also patented.

HERLAND,

3rd January, 1816

MR. GIDDY,

Sir, I have your favour of the 30th December. You are mistaken in calculating the tubes as not leaving so much fire exposed to them as in the usual way. The fire-place is 6 feet 9 inches wide, and 8 feet long, and the two tubes have nearly two-thirds of their surface, as the flue copes in a great way above the centre of the tubes. There will be about 96 feet exposed immediately over the fire-place. The surface of the fire is 54 feet, which is as much as is usually given in the largest engines.

All the remainder of the heat, in the old way, is given through the sides of the boiler, when passing round perpendicular flues; but in this way the fire, after it has passed the fire-place, will descend to the lower end of the tubes, and give heat that will ascend instead of going horizontally, as is the usual way of perpendicular flues.

If you leave home before the engine works, I will write to you every particular. If I do not chance to see you again before I leave Europe, I shall not forget to furnish you with information and specimens from America. I did not recollect to inform you when at Herland that the Foxes' engineer was here the day before you were, and said that he had worked a model about a week before with water, in the same way as I first proposed, and that the water did not get so hot as condensing water in four hours' working; neither did it escape, but worked exceedingly well, and far beyond any other engine.

I remain, Sir,

Your very humble servant,

RICHARD TREYITHICK.

The results of these experiments for using water as a medium for conveying motion and reducing the amount of loss of steam and heat in the ordinary steam-engine, are not traceable.

His use of a screw for causing a draught in the chimney, in the fourth clause of the patent, where from the character of tile engine he could not apply his former steam-blast, has been taken by some as a proof that Trevithick had used the steam-blast without under-standing its value, when in truth it was only an additional proof of his inventive resources and power of working, not only with the blast but also without it.

Propelling Vessels, etc. 6th June, 1815.

Instead of a piston working in the main cylinder of the steam-engine I do use a plunger-pole similar to those employed in pumps for lifting water, and I do make the said plunger-pole nearly of the same diameter as the working cylinder, having only space enough between the pole and the cylinder to prevent friction, or, in case the steam is admitted near the stuffing box, I leave sufficient room for the steam to pass to the bottom of the cylinder, and I do make at the upper end of the cylinder, for the plunger-pole to pass through, a stuffing box of much greater depth than usual, into which stuffing box I do introduce enough of the usual packing to fill it one-third high. Upon this packing I place a ring of metal, occupying about another third part of the depth of the stuffing box, this ring having a circular groove at the inside, and a hole or holes through it communicating with the outside, and with a hole through the side of the stuffing box; or, instead of one ring containing a groove, I sometimes place two thinner rings, kept asunder by a number of pillars to about the distance of one-third of the depth of the stuffing box, and I pack the remaining space above the ring or rings, and secure the whole down in the usual manner. The intention of this arrangement is to produce the effect of two stuffing boxes, allowing the space between the two stuffings for water to pass freely in from the boiler or forcing pump through a pipe and through the hole in the side of the stuffing box, so as to surround the plunger-pole and form the ring of' water for the purpose of preventing the escape of steam by keeping up an equilibrium between the water above the lower stuffing and the steam in the cylinder. By this part of my said invention I obviate the necessity of that tight packing which is requisite when steam of a high pressure is used, and consequently I avoid a greater proportion of the usual friction, because a very moderate degree of tightness in the packing is quite sufficient to prevent the passage of any injurious quantity of so dense a fluid as water. And I do further declare that I use the plunger-pole, working in a cylinder and through a double stuffing, either with or without a condenser, according to the nature of the work which the steam-engine is to perform.

The second part of my said invention consists in causing steam of a high temperature to spout out against the a sphere, and by its recoiling force to produce motion in a direction contrary to the issuing steam, similar to the motion produced in a rocket, or to the recoil of a gun. The mode of carrying this into effect will be readily understood by supposing a gun-barrel to be bent at about a quarter of its length from the muzzle, so that the axes of the two limbs shall be at right angles to each other, and the axis of the touch-hole at right angles to the axis of the short limb, or the limbs containing the muzzle then in the top of a boiler suitable to the raising steam of a high temperature make a hole, and insert the muzzle of the gun-barrel into that hole, so that the gun-barrel may revolve in the hole steam-tight, and let the short limb of the gun-barrel be supported in a vertical position by a collar, which will permit the breech of the gun-barrel to describe a horizontal circle, the touch-hole being at the side of the barrel. If steam of a high pressure be then raised in the boiler, it will evidently pass through the gun-barrel and spout out from the touch-hole against the atmosphere with a force, greater or less, according to the strength of the steam; and as the steam is also exerting a contrary force against that part of the breech which is opposite to the touch-hole, the barrel will recoil, and because the other end is confined to a centre, the breech end will go round in a circle with a speed proportionable to the pressure given, and may readily be made to communicate motion to machinery in general. This simple form of my invention is given merely to convey to the mind a clear idea of its nature; but in practice I do make the revolving limb, which for the sake of distinction I call the arm, much greater in its horizontal breadth than in its perpendicular thickness, in order that the arm may meet with but little resistance from the surrounding medium during its revolution, and I do introduce between the muzzle of the barrel and the boiler a steam-pipe with a cock or valve for the purpose of occasionally stopping the passage of the steam, and thereby preventing the motion of the arm, without wasting or lowering the pressure of the steam in the boiler, as well as to regulate the speed of the arm by allowing more or less steam to pass through it and I do attach another arm of equal weight with that first ascribed in an opposite direction from the centre of motion to equalize the centrifugal force, and also by acting as a balance to avoid the great friction which would otherwise take place between the barrel and the supporting collar. I do also construct this improvement with two or more arms, having similar perforations and apertures for the steam with the arm first above described, and I do, when more convenient, place the axis of revolution horizontal, or even inclined, instead of vertical and I do sometimes make the communication from the steam-pipe into the middle of the supporting collar, and from thence into the barrel, through a hole iii that part which turns in the collar, making a groove round the inside of the collar opposite to the hole in the barrel, or a groove round the barrel opposite to the hole in the collar, in order to allow the steam free passage during the whole of the revolution; and I do make the aperture through which the steam is to spout capable of being increased or decreased in its dimensions by means of a sliding piece, marked with a screw, in order to apportion the size of the aperture to the strength of the steam, the size of the boiler, and the work to be performed. In cases where great speed is required, the revolving arms should be made short, and applied immediately on the axis of motion, without the usual intervention of multiplying wheels. It is unnecessary to mention any more variation of the mode of carrying this second part of my invention into effect, since I claim as my invention the various forms of causing steam of a high pressure to pass from a boiler through one or more perforated revolving arms, and to spout out against the atmosphere from an aperture at the side, near the extremity of the arm or arms.

The third part of my invention consists in causing steam of a high temperature to act upon. water, and that water to operate upon or under a piston, without permitting the steam to come in contact with the piston; by this contrivance, also, I obviate the necessity of that tight packing which is required when steam of a high temperature acts immediately on a piston. To effect this purpose I use two vessels, standing side by side, which, for the sake of bearing high pressure, I make of a cylindric form, closed at the bottom, but connected at the lower part by a tube. One of these cylinders, which I call the steam-vessel, has a close cover, into which are inserted a steam-pipe and a discharging pipe, and in each pipe there is a valve or cock. The other vessel, which I call the piston-cylinder, is furnished with a piston, the rod of which may be attached to a pump or other machinery. To put this apparatus into operation the piston is to be placed in and near the bottom of the piston-cylinder, and the steam-vessel filled with water then, the discharging valve being shut, and the steam-valve opened, the steam will pass on the surface of the water, or upon a piece of cork or other substance floating on the surface, and by that pressure force the water down to the lower part of the vessel, through the tube, into the bottom of the piston-cylinder, and drive up the piston, without admitting any steam to pass out of the steam-vessel into the piston-cylinder. As soon as the steam has arrived near the orifice of the tube the steam-valve is to be shut and the discharging valve opened; the steam will then escape through the discharging pipe, and allow the piston to descend by its own weight, and drive the water back again into the steam-vessel, and by that means make a complete stroke, which may be repeated as often and with as much force as the size and construction of the boiler will supply the requisite quantity of steam. By the alternate passage of the same water from one cylinder to the other the water may be kept nearly to boiling heat, and consequently there will be no considerable condensation of the steam on its coming in contact with the water; and, if the little condensation which will take place should add to the quantity of water in the vessel, that extra quantity may be ejected at every stroke through a pipe and regulating cock communicating with the piston-cylinder. A double engine is to be constructed by using two steam-vessels — with their valves, to force water alternately on each side of the piston, in which case the piston-cylinder must be closed at the top, and the piston-rod worked through a stuffing box, in the usual way; or the steam-vessels may be applied to force water alternately under two single pistons, working in cylinders open at the top, to produce the effect of a double engine. And I do further declare that this part of my said invention is not capable of being used with a condenser, because the water in the steam-vessel would, if exposed to a vacuum, evaporate into the condenser, and destroy the vacuum. By lengthening the pipe of communication between the steam-vessel and piston- cylinder the power of this engine may be conveyed to a great distance from the boiler, without intermediate beams or connecting shafts. And I do further declare that, although I have described this part of my said invention as acting with a piston in the piston-cylinder, I sometimes use the plunger-pole, working through a double stuffing box instead of a piston.

The fourth part of my said invention consists in interposing the steam-vessel of the third part between the boiler and revolving arms described in the second part, so that, instead of the steam passing into the revolving arms, it shall pass on the surface of the water in the steam-vessel, and force the water through the arms and out at the apertures near their extremities against the atmosphere, and produce the revolution of the arms with more or less velocity, according to the strength of the steam in this case, also, when the steam has forced nearly all the water out of the vessel the steam-valve must be shut and the discharging valve opened for the steam to escape, and at the same time another valve or cock opened for the purpose of letting a fresh portion of water from a reservoir into the steam-vessel, when the steam is again to be admitted from the boiler, in order to force the water through the revolving arm or arms. The arms should be enclosed in a case, to prevent the steam or water being thrown at a distance, to the annoyance of the bystanders, the bottom of which case may become the reservoir water to the boiler and steam-vessel. The top of for supplying the steam-vessel should be placed at a lower level than the bottom of the reservoir, in order that the water may flow into the steam-vessel when the communication from the boiler is cut off and the steam discharged. Various modes of opening and shutting the cocks or valves are so commonly known to all persons conversant with steam-engines, that a description of them is quite unnecessary. This fourth part of my said invention is in some respects similar to the contrivance described in many books or machines by the name of Barker's Mill; but in Barker's Mill no greater power can be obtained than what arises from the perpendicular altitude of the reservoir or head of water above the place where it spouts out from the revolving arms, whereas in my invention the water acted upon and driven out by steam of a high pressure, which is well known to pass through tubes with very little friction compared with water, a much greater power will be obtained from the same quantity of water; and as the water, after it has passed through the revolving arms, may be made to flow back again into the steam-vessel, to be driven through the revolving arms by a succeeding portion of steam, a small quantity of water may be made to work the engine a long time. By putting flat plates or leaves upon the revolving arms within the case I produce a current of air in the manner of a winnowing machine for blowing the fire, and I do sometimes place in the flue a screw or set of vanes, somewhat similar to the vanes of a smoke-jack, which screw or vane I do cause to revolve, by connection with the steam-engine, for the purpose of creating an artificial draught in the chimney, always proportioned to the size of the fire-place and situation of the chimney. By either or both of these means I obviate the necessity of a tall chimney when the engine is used for portable purposes.

The fifth part of my said invention, and that which comes under the second part of my title, consists of a mode of propelling, drawing, or causing., ships, boats, and other vessels to pass through the water, which purpose I effect by constructing a worm or screw, or a number of leaves placed obliquely round an axis, similar to the vanes or a smoke-jack, which worm, screw, or vane shall be made to revolve with great speed, having the axis in a line with the required motion of the ship, boat, or other vessel, or parallel to the same line of motion the obliquity of the thread of the worm, screw, or leaves, admits of considerable variety, according to the degree of velocity given to it and speed required, and according to the power with which it is driven, but as a general medium I by preference contrive that the thread of the screw at its outer edge shall make with its axis an angle of about thirty degrees. This worm is in some cases to revolve in a fixed cylinder, in others to revolve together with the cylinder, similar to the screw of Archimedes, but generally to revolve in the water without any cylinder surrounding it. This worm or screw may be made to revolve in the water at the head of the ship, boat, or other vessel, or at the stern, or one or more worms may revolve on each side of the vessel, as may most conveniently suit the peculiar navigation on which the ship, boat, or vessel is to be employed. In some cases when the screw is to work at the head of a ship, it is to be made buoyant, and move on a universal joint, at the end of an axle, turning in the bow of the ship, in order that the screw may accommodate itself to the unevenness of the waves. And I do further declare that, in order to make the boiler of a high-pressure steam-engine of very light materials for portable purposes, and at the same time strong for resisting the pressure, as well as for exposing a large surface to the fire, I do construct the said boiler of a number of small perpendicular tubes, each tube closed at the bottom, but all opening at the top into a common reservoir, from whence they receive their water, and into which the steam of all the tubes is united.

In witness whereof, I have hereunto set my hand and seal, this Twentieth day of November, in the year of our Lord One thousand eight hundred and fifteen.

RICHARD (L.S.) TREVITHICK.

The variety and extreme range of inventions made known in this patent specification cannot be other than superficially spoken of in this chapter, including, as they do, multitubular boilers, expansive high-pressure steam, the screw-propeller, and the recoil engine.

The absence of a drawing illustrating his claims is to some extent made good by reference to other drawings. Claim 1 is for an application of the pole, either in a puffer or vacuum engine, shown in Wheal Prosper drawing, chapter xix., — to marine purposes, modified if necessary by the water medium of communicating power in Claim 3, shown in Trevithick's sketch, page 371. Claim 2 is for the recoil or rotary engine, sketched by Trevithick, page 364, worked by the rush of strong steam against the atmosphere, or by the water medium described in Claims 3 and 4. Claim 5 is for the famous screw-propeller, described in Trevithick's letter, page 348, and includes the no less famous multitubular boiler, as sketched by Trevithick, page 370: as the customary puffer-engine blast-pipe could not be applied, draught was produced by a screw in the chimney.

Sources of Information

- ↑ Richard Preen's recollections, taken at Bridgenorth, 1869.