J. Bagshaw and Sons

of Victoria Foundry, Batley

1834 Company established

1875 Large compound beam mill engine[1]. It is not clear whether this engine was made by Bagshaw, or whether their involvement was limited to compounding. This involved supplying a new beam with an upturned horn. To this horn was connected the connecting rod of a new small bore, long stroke piston. The new cylinder was attached to the bed-plate outboard of the crankshaft. [2]

1877 Patent. '2231. To John Bagshaw and Walter Bagshaw, both of Victoria Foundry, Batley, in the county of York, for the invention of "an improved equilibrium valve for water and other fluids."'[3]

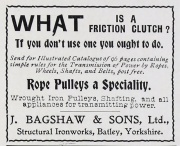

1881 'EXHIBIT BY A LOCAL FIRM AT THE CRYSTAL PALACE. Many of our readers will doubtless remember that September last we drew attention to an important invention for factories, made by Messrs. John Bagshaw and Sons, Victoria Foundry, Batley, namely— “Addyman’s American Friction Clutch,” and we have now been favoured with the inspection of very beautiful working model of the invention, made the same firm, to be forwarded to the Crystal Palace, for the forthcoming exhibition. The model is fixed a large board, painted in imitation of brick wall, to which the bearers for a small shaft are attached. The shaft, &c , are highly polished, and the simplicity of contrivance is clearly shown. For the information of those who did not see our previous description of the “clutch,” we may state this consists of a driving pully with an expanding friction ring inside, into which a wedge is moved in or out simply turning a small hand-wheel, and, with the greatest ease, almost instantly throws in or out of motion any shaft or machine to which it is attached. In the model there is both an upright and horizontal shaft, and all or any portion of them can be worked or stopped at pleasure. Nearly all the large firms in our own district have adopted these clutches in their mills, and the firm have received orders from almost all parts of the world where manufacturing is carried on. We are informed that Alexander Redgrave, Esq., Her Majesty’s Inspector of Factories ; Mr. A. Beaumont, Sub-inspector for this district ; and Major Stulpengel, chief official in the Factory Offices of the German Government, have each visited the works of Messrs. Bagshaw, and inspected the appliance, the results of which they highly approve. We have no doubt it will be viewed with considerable interest at the Exhibition.'[4]

Note: The UK licence was previously held by Grayson and Hardisty of Hunslet:

' NEW AMERICAN CLUTCH (Addyman's Patent).

The most perfect and simple clutch yet invented. Can be used either as a Friction Pulley or as a Friction Coupling. Invaluable where portions of shafting want stopping occasionally, or where portions of shafting require driving separately, or in place of fast and loose pulleys. Can be seen working at Messrs. Hebbert and Co (Leeds)., Cloth Furnishers, Grace-street Mills, Leeds.

For full particulars apply to the Sole licensed makers -

Messrs. GRAYSON AND HARDISTY, MACHINISTS, HUNSLET, LEEDS'[5].

Note: An 1877 advertisement added the fact that information could be obtained from the makers 'or at the offices of the Patentee, C. H. Addyman, Old Bank Chambers, Leeds.'

1882 'It has been remarked that there is no mechanical appliance that has been the subject or more patents or contrivances than the clutch. Many ingenious devices have been constructed, and several of them have been applied to machinery with more or less success. Although a Yankee invention Addyman's friction Clutch, our article that for years has stood the test in the United States, is being manufactured by Messrs. G. Bagshaw & Sons, Victoria Foundry, Batley, Yorkshire, and from the great success attending its application to machinery in various extensive works in England and on the Continent, the firm just mentioned have received and are daily receiving orders on all hands, for, as one firm writes them "a number of clutches, as they supply a want." British, American and Continental scientific newspapers speak of the merita of Addyman's clutch in the highest strains while its principle is approved by all the leading engineers of the day. Wherever indeed machinery is employed, in wire works, cotton or silk mills, bleach or paper works, its application has obvious advantages, among which may be mentioned the fact that accidents are avoided, that it can be worked while in motion, that wear and tear are reduced, that it is easily adjusted, and is not liable to get out of order. It is, it may be stated, the only clutch that allows of lubrication on friction surfaces, by which wear and tear are reduced to a minimum. Those who have seen Addyman's clutch at work have formed a high opinion regarding its value, and their idea is that it should be applied to every line of shafting in a workshop. The clutch, it has already been stated, is manufactured by Messrs. Bagshaw, Batley, and when its capabilities are better known in Glasgow and the surrounding district, as they are bound to be in a short time, its general application to the machinery, in our extensive works may be safely predicted. The high standing of Messrs. Batley as manufacturers of machinery of every description is a sufficient guarantee that each clutch turned out by them may be relied upon as being perfect so far as finish and workmanship are concerned.'[6]

1883 Provided equipment for the Giants Causeway, Portrush and Bush Valley Railway and Tramway Co, including shafting and gearing.[7]

1884 Partnership change. '... the Partnership heretofore subsisting between us the undersigned, John Bagshaw, Walter Bagshaw, and Charles Horsfield Bagshaw, carrying on business as Iron Founders, Engineers, and Millwrights, at Batley, in the county of York, under the style or firm of J. Bagshaw and Sons, has been this day dissolved by mutual consent. All debts due to or owing by the said late partnership will be received and paid by the said Walter Bagshaw and Charles Horsfield Bagshaw and Arthur Bagshaw, by whom the said business will in future be carried on under the above style or firm...'[8]

1888 Issued catalogue of wrought iron pulleys, shafting, friction couplings and friction clutches. [9]

1889 'On Friday afternoon last week the new iron foot-bridge across the river Aire at Buck Hill, was formally declared open to the public by the members of the Idle and Baildon Local Boards..... The Idle Local Board, having arranged all preliminaries, accepted the tender of £778 of Messrs J. Bagshaw and Sons, engineers, Batley, in accordance with the design and drawings (approved by all the signatures to the agreement) of Messrs Kendall and Bakes, architects, of Idle. The work has now been completed, the result being seen in the substantial structure now spanning the river on the Charlestown side of Buck Mill, about twenty yards below the old steppingstones, the position being selected by the late General Stansfield. The approaches at either end of the bridge are six feet wide, sloped gradually to level of bridge platform, well macadamised, and protected by fence walls. The superstructure of the bridge, which is painted red, stands on three piers and two abutments, the foundations to the piers and abutments being made a depth of four feet below the bed of the river, and constructed of solid cement concrete. The piers, which have angular cutwaters and abutments, are built of sandstone ashlar, from Windhill Wood End quarries, filled in solid with rubble and cement. The coping, or girder foundation stones, consist of large sandstone ashlar blocks. The superstructure, which is about twelve feet above the river low water level, consists of three spans measuring 88 feet between centre of bearings, making the total length of the bridge 264 feet. The whole of the superstructure is constructed entirely of wrought iron. The main girders are of the single lattice type, seven feet deep, and placed six feet (the width ot the bridge) centres apart with parallel horizontal booms, vertical struts, and diagonal ties placed eight feet centres apart carrying a three-inch plank platform on the bottom flanges. The booms consist of tee irons and flange platers rivetted together. The diagonals are flat bars, and the verticals are angle irons rivetted to booms. The girders are braced together and stiffened by means of a complete and ornamental system of horizontal and diagonal wind bracings on top bottom, and sides. The fixed ends of the girders are carried on bearing plates, bedded on sheet lead upon the foundation stones, and well and securely bolted down, while the end plates of the girders, at the joints of the piers, are also well bolted together. Suitable plank plinth, iron railing, and hand-rail have been placed alongside each girder. ...' [10]. The bridge was also described and illustrated in The Engineer [11]. See also this 2021 newspaper article.

1890 'Applications for patents :— Walter Bagshaw, Charles Horsfield Bagshaw, and Arthur Bagshaw, of Batley, for "An improved friction clutch." [12]

1891 Released a catalogue of their wrought iron pulleys, shafting and friction couplings. [13]

A JB&S friction clutch is fitted to the steam engine made by J. Culverwell at Westonzoyland Museum.

1913-15 Produced the J. B. S. cyclecar.

1922 Directors: Gilbert K. Walker, Ernest S. Walker

See Also

Sources of Information

- ↑ * 'Stationary Steam Engine Makers Volume 1' Compiled by George Watkins, Catalogued by A. P. Woolrich, Landmark Publishing Ltd. ISBN 1-84306-200-3. This reproduces an engraving of the engine from The Engineer, 5 November 1875

- ↑ ‘The Textile Mill Engine, Part 1’ by George Watkins: Landmark Publishing Ltd.

- ↑ The London Gazette Publication date:29 June 1877 Issue:24477 Page:3924

- ↑ Dewsbury Reporter - Saturday 21 May 1881

- ↑ Leeds Mercury - Saturday 16 December 1876

- ↑ Glasgow Mercantile Advertiser - Tuesday 20 June 1882

- ↑ Batley Reporter and Guardian, 6 October 1883

- ↑ The London Gazette Publication date:4 January 1884 Issue:25305 Page:93

- ↑ The Engineer of 27th April 1888 p338

- ↑ Shipley Times and Express - Saturday 20 April 1889

- ↑ The Engineer 1889/08/02

- ↑ York Herald - Friday 7 February 1890

- ↑ The Engineer 1891/04/10